Journey of future architect

When Kim Seu Seu’s son had to submit a creative portfolio together with his enrolment application for Architecture School at Auckland University, he decided that he wanted to further demonstrate his capabilities, innovative mind and determination to do well by submitting some unique pieces of furniture as part of his body of work for 2019.

Assessing capabilities in the early stages

As with most applications, he had a strict deadline to meet, and within the given time frame he was also completing final exams and working, which meant that in the end, he could only complete one piece of furniture.

But that’s not to say it wouldn’t be a unique piece that would most definitely catch people’s eye!

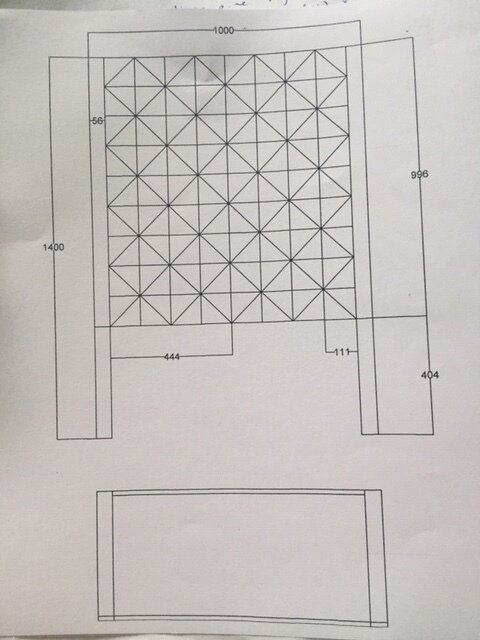

After the design process was complete, he had to start thinking about the physical manufacturing process and the most efficient avenue.

It was clear that doing everything by hand would involve a labourious and time-intensive process, which would include building a jig, using a router tool and chiseling out all the corners - none of which he had time for at that stage.

Hunting for a manufacturer

The specifications weren’t overly straightforward - and the 3D effect of the doors was a key feature of the design. This project needed a high level of both skill and technology to complete successfully.

Kim scouted around for partners to help with the manufacturing of the project and went to a couple of places for quotes, but all of them said that the corners were too much work.

This is when Kim approached Cutshop®, who, without hesitation, agreed to complete the detailed work for the cabinet design and bring it to life.

“Everyone that I dealt with was friendly and helpful from front office to Shane, who went the extra mile for us. The work done by Cutshop®was outstanding - and we got it in on time. I’d definitely recommend Cutshop® to others and I’d use them again in the future.”

Once the cabinet was put together, all that was left to do was paint it black to make it ready for viewing by key decision makers.

It was a rewarding process for all involved, and showcased a prime example of just how much creativity, innovation and originality can be brought to life in the Cutshop® factory.